The Evolution of Automated Tank Gauging Systems in 2025

Introduction

In a world increasingly driven by automation and compliance, Automated Tank Gauging (ATG) systems are experiencing a technological renaissance. These systems are essential for managing inventory, preventing environmental hazards, and streamlining compliance in industries such as fuel distribution, chemicals, agriculture, and utilities. This blog examines the evolution of ATG systems in 2025 and how ATG Advisors—backed by our strategic technology partners—empowers clients to modernize tank monitoring, enhance efficiency, and avoid costly penalties.

And yes—we get the irony. Our name is ATG Advisors, but don’t worry—we’re not in the business of installing sensors on tanks ourselves. We’re the ones who make sure the people who do it are doing it right, on time, and without getting you fined into oblivion. Automated Tank Gauging may be our namesake acronym by coincidence, but delivering automated strategy, transparency, and growth? That part's entirely intentional.

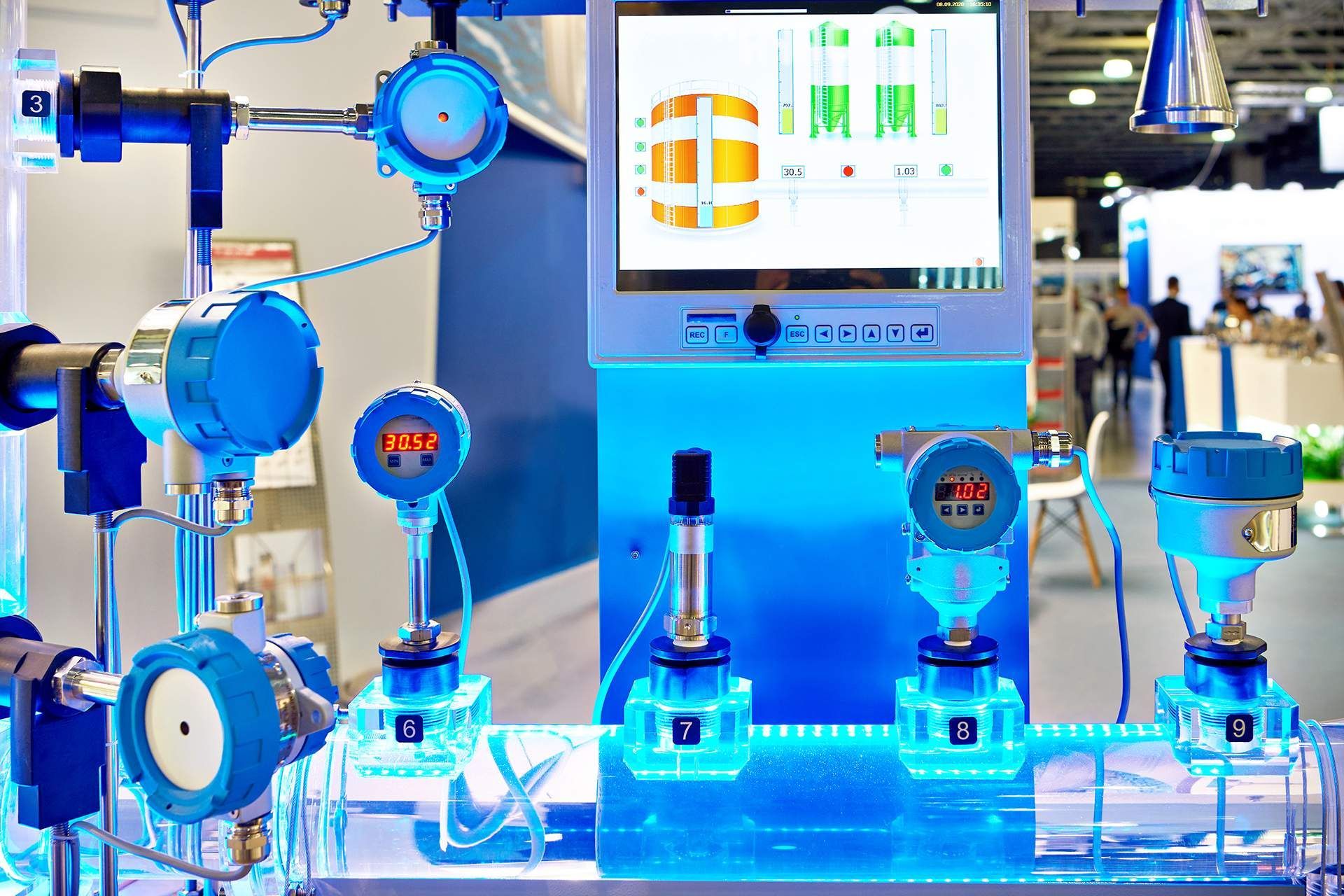

What is an Automated Tank Gauging System?

An ATG system is a suite of hardware and software that continuously monitors the level, volume, temperature, and integrity of storage tanks—especially those containing fuel, chemicals, or other regulated liquids. These systems help:

- Prevent overfills and leaks

- Track inventory in real-time

- Ensure compliance with local, state, and federal regulations

- Detect water intrusion and temperature fluctuations

ATG Advisors’ Role: We evaluate operational requirements, recommend ATG solutions aligned with business goals, and coordinate deployment through certified installers and compliance specialists.

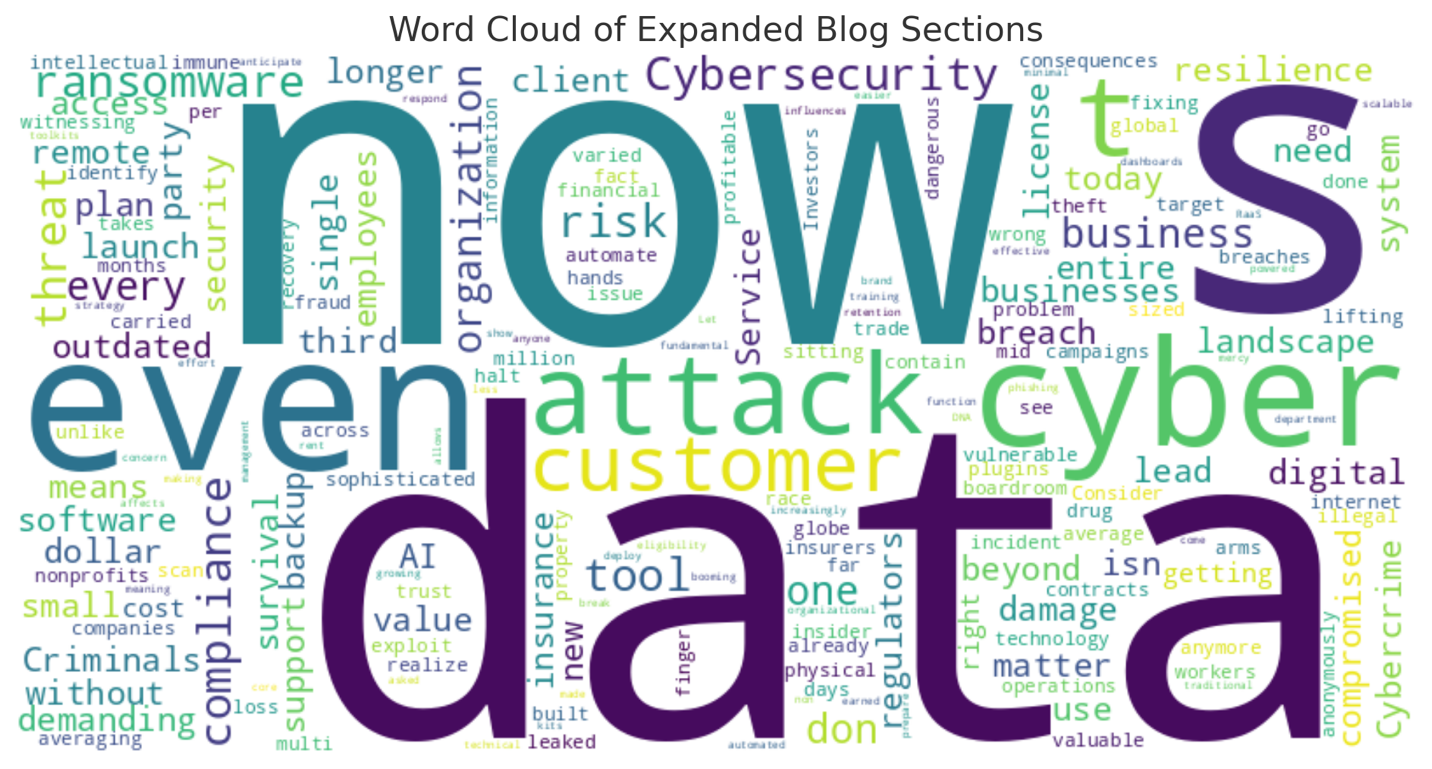

Technological Advancements Defining 2025

ATG systems have rapidly evolved in the last five years. Today’s smart tank solutions include:

- Cloud-Connected Dashboards: Allow remote monitoring across multiple sites in real time

- AI-Based Leak Detection: Analyze data trends to flag subtle anomalies before environmental damage occurs

- Sensor Redundancy: Multi-layered verification improves accuracy and minimizes downtime

- Integrated Reporting: Automate compliance submissions to EPA and state agencies

- Mobile Apps: Empower field teams with access to live data and alerts on-the-go

ATG Advisors’ Role: We stay ahead of the curve by monitoring ATG industry trends and facilitating integration with modern ERP systems, mobile platforms, and compliance portals. We don’t just think outside the box—we automate and audit the box, then tell you if it’s leaking.

Use Cases Across Industries

While fuel stations are the most recognized ATG users, many sectors rely on tank monitoring systems:

- Agriculture: Tracks fertilizer, pesticide, and water storage levels

- Utilities: Monitors water treatment chemicals and backup fuel supplies

- Food and Beverage: Ensures safety in liquid storage such as oils, syrups, or CO2

- Chemical Manufacturing: Enhances safety and regulatory visibility

- Transportation & Logistics: Manages fuel depots and refueling infrastructure

ATG Advisors’ Role: Our consultants help clients in these sectors determine ideal sensor configurations, establish alert thresholds, and integrate ATG data into broader operational systems. We’re the rare advisors who get excited about tank metrics—and know what to do with them.

The Compliance Landscape: Why Accuracy Matters

ATG systems are not just operational tools—they are regulatory lifelines. The EPA mandates leak detection, release reporting, and routine inspections for underground storage tanks. Fines for noncompliance can reach into six figures, not including cleanup costs or reputation damage.

ATG Advisors’ Role: We help clients prepare for EPA audits, maintain recordkeeping compliance, and adopt leak detection systems certified under federal and state guidelines. Think of us as your compliance GPS—minus the annoying voice, plus actual results.

Environmental and Financial Benefits

By preventing leaks and overfills, ATG systems:

- Reduce environmental contamination

- Minimize product losses

- Lower insurance premiums

- Enhance safety protocols

- Prevent shutdowns or legal actions due to spills

ATG Advisors’ Role: We provide ROI modeling to illustrate the economic benefits of modern ATG systems. For many clients, investments are recouped within 12–18 months through reduced fines, optimized inventory management, and tax incentives. Yes, it turns out being responsible can actually pay.

ATG System Integration with Enterprise Operations

Modern ATG systems are no longer standalone devices. Integration is now essential:

- ERP/Inventory Software: Automate reordering and replenishment

- SCADA and Facility Controls: Sync tank data with broader operational dashboards

- Accounting Systems: Align inventory usage with financial projections

- Mobile Field Services: Send alerts and work orders to on-site technicians

ATG Advisors’ Role: We lead these integrations through API configurations, vendor coordination, and business process redesign. We make sure your smart tanks talk to your smart books—because every drop (and dollar) counts.

Common Pitfalls and How to Avoid Them

- Relying on Legacy Hardware: Older sensors often miss slow leaks

- Manual Data Entry: Increases the risk of compliance errors

- Untrained Staff: Misinterpret alerts or ignore routine maintenance

ATG Advisors’ Role: We conduct system assessments, recommend upgrades, train internal teams, and offer continuous monitoring support through our technology partners. We’re the people you call when you realize the last inspection report was typed up on a typewriter.

Innovation Outlook: What’s Next?

Looking ahead, ATG systems will incorporate:

- Satellite Connectivity: For monitoring in rural or remote areas

- Edge AI Processing: Reduces cloud dependency by enabling local analytics

- Blockchain Recordkeeping: Tamper-proof audit trails for compliance

- Automated Drones: For physical tank inspection and aerial data mapping

ATG Advisors’ Role: We are actively exploring these innovations with our partners, helping clients future-proof their tank operations and regulatory positioning. If there’s a smarter way to track, detect, or analyze your tanks—we’re probably already piloting it.

Conclusion

As environmental compliance, automation, and operational efficiency continue to converge, ATG systems are more valuable than ever. Organizations that modernize tank monitoring now will not only reduce risk and improve visibility—they will gain competitive edge. ATG Advisors provides tailored consulting, implementation oversight, and long-term ATG strategy guidance to help you build a smarter, safer, and more compliant operation.

And no, despite the shared acronym, we’re not installing sensors ourselves. But we are the ones who make sure your ATG system—and your business—is tank-tight, future-ready, and acronym-approved.