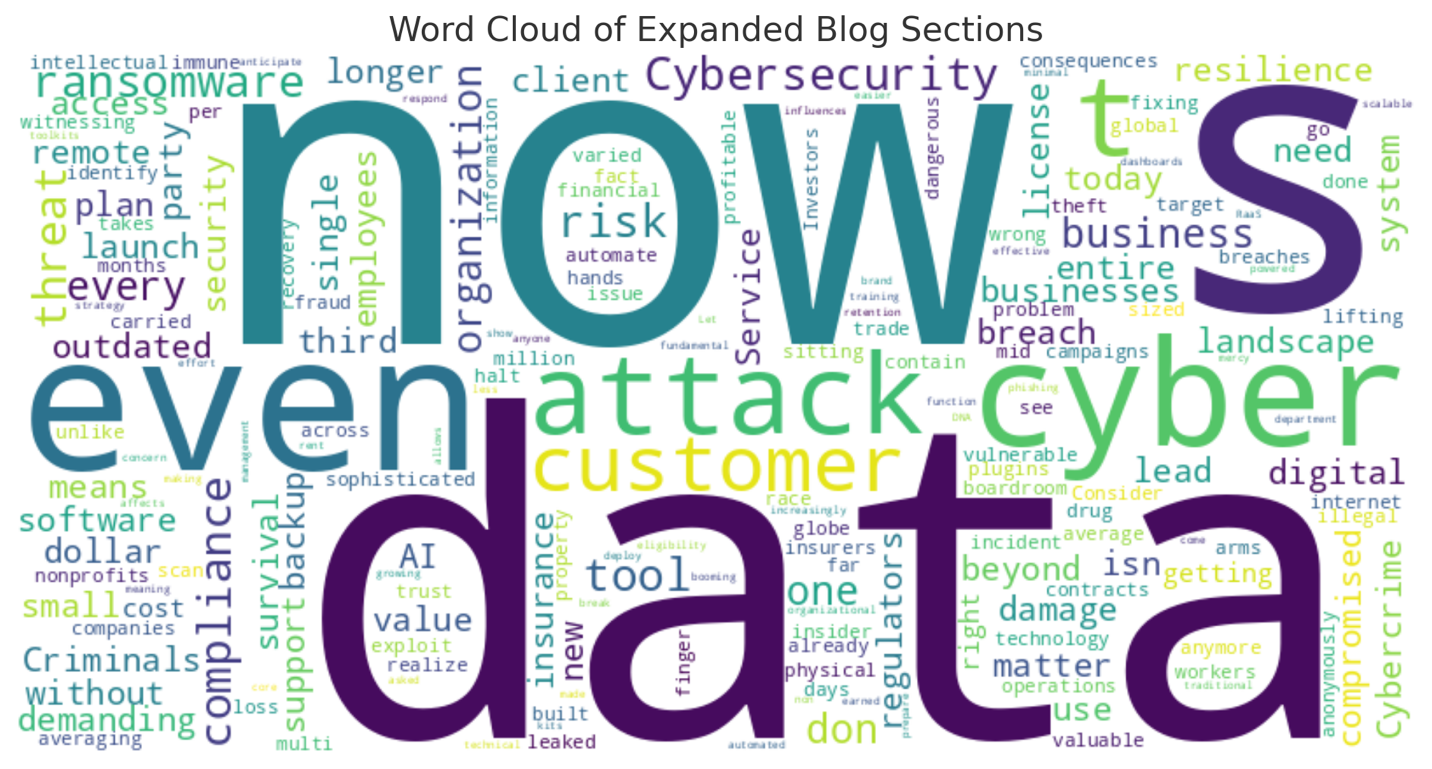

Sustainable Manufacturing: Integrating Clean Technologies for a Greener Future

Introduction

Sustainability in manufacturing is no longer a niche initiative—it’s a strategic imperative. Businesses are under pressure to reduce emissions, conserve resources, and operate responsibly. Consumers, regulators, and investors are all demanding transparency and action.

This blog explores how sustainable manufacturing is evolving and how ATG Advisors and our strategic technology partners support organizations in deploying clean technologies, achieving compliance, and building long-term operational and environmental resilience.

The Case for Sustainability in Manufacturing

From climate change to global resource depletion, sustainability challenges are intensifying. Manufacturers face increasing scrutiny over their environmental impact—particularly carbon emissions, waste output, and energy usage. ESG (Environmental, Social, and Governance) performance is now a key metric for competitiveness, especially among publicly traded companies and global supply chains.

Sustainable manufacturing doesn’t just benefit the planet—it improves efficiency, reduces costs, and opens new revenue opportunities.

ATG Advisors' Role: We work with organizations to build sustainability roadmaps, integrate ESG reporting frameworks, and identify operational areas for energy and material efficiency improvements.

Key Metrics for Environmental Impact

To implement meaningful change, companies must measure:

- Carbon Emissions: Scope 1 (direct), Scope 2 (indirect from purchased energy), and Scope 3 (supply chain emissions).

- Energy Use: Electricity, gas, and renewables.

- Water Usage: Consumption and discharge.

- Waste Generation: Hazardous and non-hazardous waste.

- Material Efficiency: Percentage of recycled or renewable materials.

ATG Advisors’ Role: We help clients define KPIs, implement tracking systems, and automate sustainability dashboards aligned with frameworks like GRI and SASB.

Clean Technology Solutions for Industry

Sustainable manufacturing requires integrated technologies such as:

- Solar and Wind Power: Offset reliance on fossil fuels.

- Energy Storage Systems: Ensure continuity and optimize usage.

- LED and Smart Lighting: Reduce electrical consumption.

- Efficient HVAC Systems: Improve indoor air quality while lowering costs.

- Waste-to-Energy Systems: Convert factory waste into usable energy.

- IoT Energy Monitoring: Track real-time usage and detect inefficiencies.

ATG Advisors’ Role: We assess site readiness, coordinate vendor sourcing, oversee installation, and manage post-implementation monitoring in partnership with clean energy providers.

Circular Economy in Practice

Circular economy principles aim to eliminate waste and reuse resources. In manufacturing, this means:

- Designing products for durability and recyclability

- Using biodegradable or recyclable packaging

- Implementing reverse logistics

- Remanufacturing and refurbishing components

ATG Advisors’ Role: We design circular business models and supply chain strategies that maximize material reuse, reduce environmental impact, and improve profitability.

Government Incentives and Policy Drivers

Sustainable initiatives are often incentivized through:

- Federal and State Tax Credits: For solar, wind, and EV fleet adoption.

- Grants and Rebates: Energy efficiency upgrades and R&D for clean tech.

- Cap-and-Trade Programs: Reduce emissions with market incentives.

- Public Procurement Preferences: Favoring environmentally certified vendors.

ATG Advisors’ Role: We help clients apply for green incentives, ensure proper documentation, and integrate sustainability planning into tax and compliance strategies.

Reporting and Certification Frameworks

Transparency is essential. Stakeholders want to see progress, not just promises. Widely recognized reporting standards include:

- ISO 14001: Environmental Management Systems

- GRI (Global Reporting Initiative): Standardized impact disclosures

- CDP: Climate performance disclosure platform

- SASB: Financially material ESG metrics by sector

ATG Advisors’ Role: We build custom ESG reports, manage stakeholder engagement, and ensure clients meet reporting obligations with accuracy and clarity.

Real-World Success: Eco-Efficiency in Action

A mid-sized food processing plant in the Southeast U.S. implemented an energy retrofit program including solar panels, variable frequency drive (VFD) motors, and water reclamation systems. Within two years, the company:

- Reduced energy use by 37%

- Cut water consumption by 21%

- Received $400,000 in tax incentives

- Improved ESG rating with investors

ATG Advisors’ Role: We coordinated the utility audit, calculated the ROI, assisted with incentive applications, and designed the data dashboards for annual ESG reporting.

Implementation Steps for Sustainable Manufacturing

- Assessment: Evaluate baseline environmental performance

- Goal Setting: Align with internal objectives and external mandates

- Technology Identification: Prioritize high-ROI upgrades

- Vendor Selection: Use certified clean tech partners

- Deployment: Manage timelines and installation quality

- Monitoring and Optimization: Continuous improvement using real-time analytics

ATG Advisors’ Role: We provide project management, ROI tracking, and performance reporting—ensuring sustainability efforts stay aligned with financial and operational goals.

Challenges and How to Overcome Them

- High Upfront Costs: Mitigated through tax credits, grants, and leasing options

- Change Management Resistance: Solved with internal engagement and training

- Data Gaps: Solved through IoT deployment and analytics integration

ATG Advisors’ Role: We educate stakeholders, build executive support, and deliver comprehensive sustainability plans tailored to each client’s resources and market.

The Future of Sustainable Manufacturing

The future is data-driven, decentralized, and circular. Expect:

- AI-powered energy forecasting and emissions modeling

- Blockchain-based supply chain transparency

- Localized microgrids and energy independence

- Regulatory pressure and ESG-linked financing

ATG Advisors’ Role: As sustainability becomes central to strategy, we continue evolving our tools and partnerships to help clients lead—not just comply—with the future of clean manufacturing.

Conclusion

Sustainable manufacturing is more than a trend—it’s a business imperative. Companies that embrace clean technologies, resource efficiency, and ESG leadership will gain a competitive advantage and create lasting value.

ATG Advisors helps clients turn sustainability into strategy with holistic solutions, innovative partners, and measurable results.